MVR Technology delivers advanced machinery for FSTPs, Weighbridges, and sewerage systems. We undertake turnkey government projects focused on automation in sanitation, waste management, and public infrastructure. Our expertise also includes civil construction and long-term project maintenance, ensuring end-to-end solutions with lasting impact.

MVR Technology, a division of MVR Group of Industries, is headquartered in Guntur, Andhra Pradesh. We boast over three decades of excellence in the agro-industry, being the largest cotton processor in Andhra Pradesh and Telangana since 1996. In 2014, we diversified into the manufacturing of mechanical and electrical components by establishing our plant in Guntur District, A.P., equipped with fully automated processes.

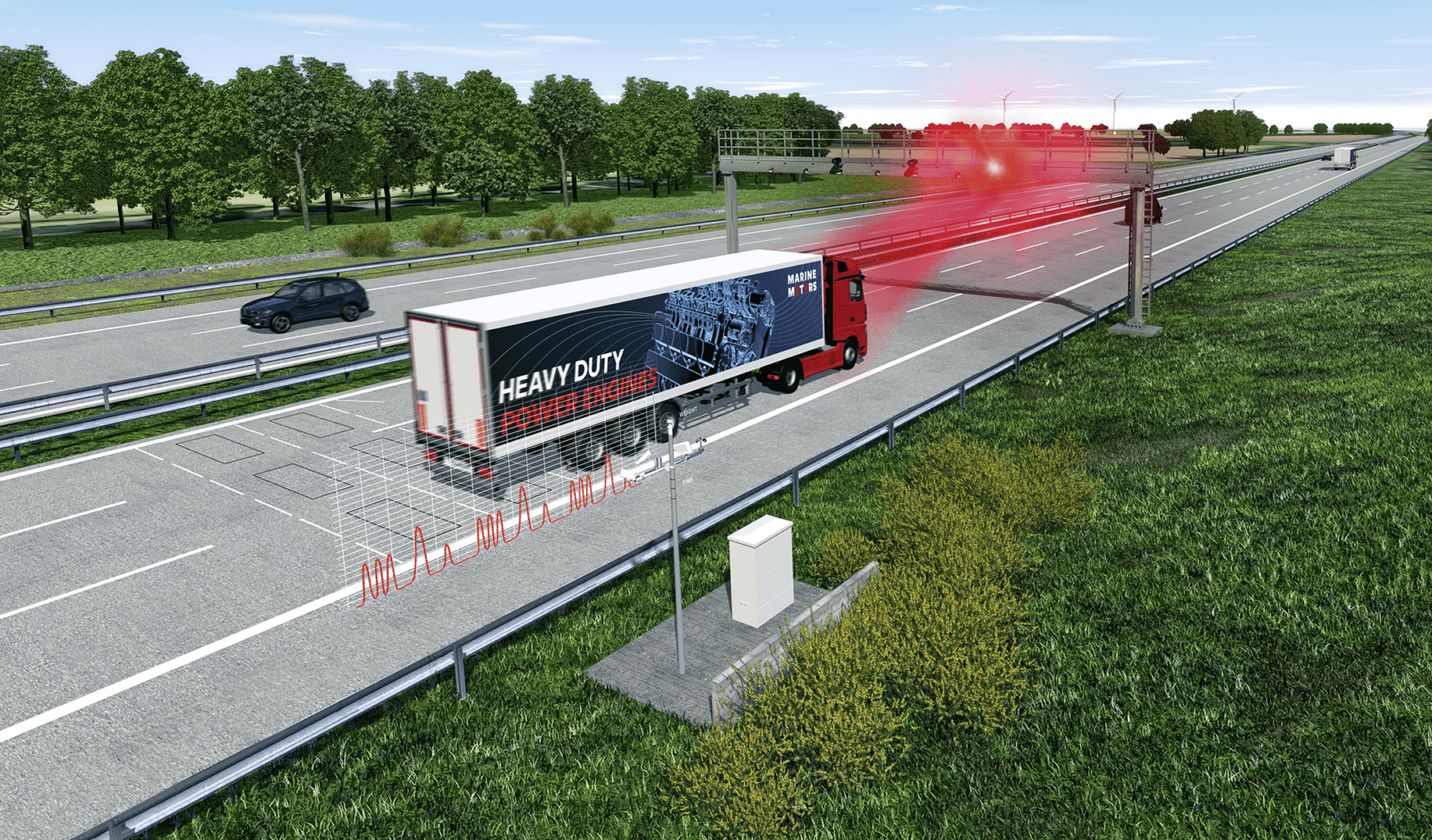

At a later stage, we also began working with various state governments, starting in 2014 with fully automated PDS (Public Distribution System) solutions. We then implemented Weigh-in-Motion systems for NHAI, becoming the sole contractor to execute the project across 19 Indian states. We also took part in the commissioning of Growth Monitoring Devices in 14 states under the Government of India’s Poshan Abhiyaan scheme. Parallelly, we initiated R&D in sewerage systems and the solid waste management sector by establishing a core factory for the development of new sewerage technologies, entirely in-house and fully automated — the first of its kind in India, now patented.

Today, MVR Technology has been awarded multiple state government sewerage projects from various Municipal Corporations and Municipal Councils. Since 2016, we have been awarded contracts for the provision of sewerage facilities in around 475 cities, including Operation & Maintenance (O&M) contracts for 10 to 20 years.

We are proud to be the only company in Asia to implement Faecal Sludge Treatment Plants (FSTPs) with an awarded capacity of 7,900 KLD (as of Dec 2024) — out of which approximately 3,600 KLD capacity plants have already been successfully commissioned, and O&M is in progress. The company stands among the top in Asia and globally in this sector. Our philosophy is centered around a WIN-WIN approach, emphasizing customer satisfaction as the cornerstone of our success. We are committed to delivering zero-defect products and services, ensuring timely project execution, and providing exceptional post-commissioning support, thereby solidifying our reputation for quality and reliability.

Our state-of-the-art manufacturing facility in Guntur is the largest of its kind in India for producing sewerage-related equipment. This advanced plant embodies our Make in India initiative and integrates both electrical and mechanical production, with the capacity to manufacture sewerage equipment required for four towns per day.

The FSTP project by our team focuses on developing a practical and sustainable solution for managing faecal sludge in urban and peri-urban areas. This initiative is essential for improving sanitation in regions lacking underground drainage systems. Our plant is designed to collect, treat, and safely dispose or reuse sludge from septic tanks and pit latrines. Through efficient treatment processes such as screening, drying, and composting, we aim to reduce environmental impact and promote public health. This project reflects our commitment to creating cleaner and healthier communities.

.jpeg)

To ensure smooth and uninterrupted plant operations, a dedicated Command & Control Center (CCC) has been established. This control room acts as the digital brain of the FSTP, where all treatment stages, equipment performance, and safety parameters are monitored in real-time. The CCC enables efficient decision-making, remote diagnostics, and preventive maintenance — helping us maintain high operational standards and quick responses to any alerts.

.jpeg)

Employees

KLD Total Capacity

KLD Live

States Covered

| Town | District | Capacity | Image |

|---|

Comprehensive health coverage for employees and their families.

Opportunities to grow, upskill, and lead exciting projects.

We believe in flexible work with time for family and hobbies.

Get recognized and rewarded for your contributions.

At our company, we believe in fostering a dynamic and supportive work environment. We offer excellent opportunities for growth, competitive salaries, and comprehensive benefits. Join our team and be a part of something extraordinary!

Guntur

Vinjanampadu, Vatticherukuru,Andhra Pradesh 522017

Phone: 040-65697677, 040-65697678

Email: mvrtech@mvrtech.org

#207, Gowra Fountain Head, Vittal Rao Nagar Rd, HUDA Techno Enclave,

HITEC City, Hyderabad, Telangana 500081

Phone: 040-65697677, 040-65697678

Email: mvrtech@mvrtech.org